PCBA testers are used to program and test safety and gas gauge PCB assemblies, before they are assembled into complete battery packs. Such “early in the process” testing assures correct assembly of safety and gas gauge PCBAs. Early testing and verification of PCBA prevents assembly of “bad boards” into complete battery packs, eliminating time waste to assemble “bad packs” and hence reducing over all assembly cost, while increasing over all throughput of the production line. PCBA testers simulate presence of battery cells during the test process.

Examples of PCBA (Printed Circuit Board Assembly) testers developed by and available from FaberPC Enterprises:

Stand-alone/simple PCBA Tester.

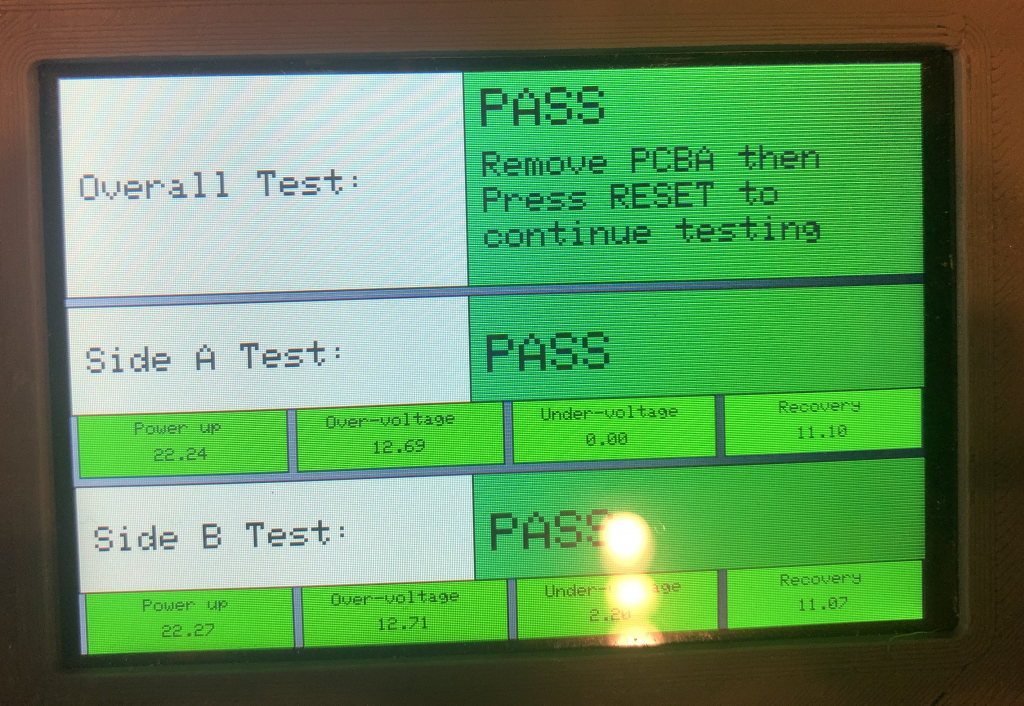

This is a lower cost PCBA tester, designed to test one predefined type of safety PCBA. This design features embedded control circuit, custom designed for type and configuration of tested PCBA. The setup also includes a LCD display to communicate directions and results to operator as well as nest/fixture designed for target PCBA. Most common executed tests including power-up test, over-voltage, under-voltage and recovery. This type of tester rarely features communication functions to interact with gas-gauge IC.

Stand-alone PCBA tester

Stand-alone PCBA tester display

Multipurpose/universal PCBA Tester

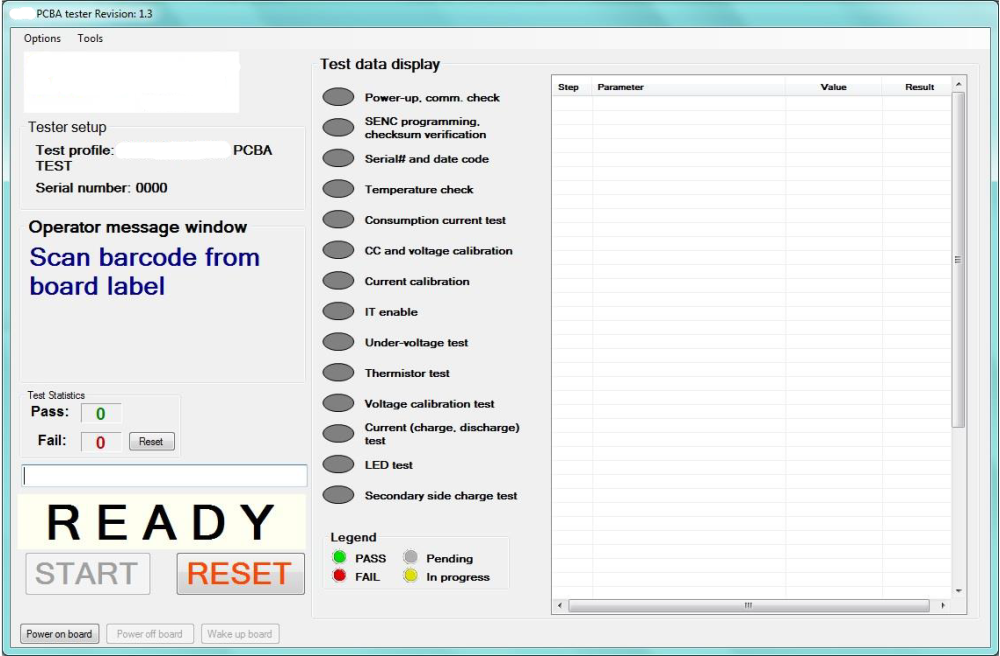

This is much larger (and much more expensive) PCBA tester, designed to test multiple versions and types of PCB assemblies. This type of test equipment includes control PC, custom designed control hardware (with relays, communication interface and sequence control hardware), as well external measurement and test devices (electronic load, power supplies, DMM, etc.). Universal PCBA Tester features test profiles, which determine test sequence, enable or disable process steps (like programming, calibration, specific circuit features verification, etc.).

Tasks executed by Universal PCBA tester may include :

– gas gauge IC programming

– gas gauge IC calibration

– quiescent current measurement

– safety feature verification (over-voltage, under-voltage, over-current protection)

– enable/system present check

– thermistor and ID resistor check

– calibration verification

– LED function check

– secondary side testing

Multipurpose PCBA tester user interface

Multipurpose PCBA tester display and fixture

Measurement equipment used with PCBA tester

PCBA tester main control box